The world of welding is a fascinating universe of techniques and machines, each designed to cater to specific needs and welding preferences. The four primary welding methods – MIG, TIG, ARC, and Plasma – offer a diverse set of features and capabilities. Understanding the differences between these methods is crucial for choosing the right welding machine for your projects. Let’s take a deep dive into the welding universe to compare and contrast these welding techniques.

What is MIG Welding?

MIG welding, or Metal Inert Gas welding, is a versatile process. It involves a continuous solid wire electrode being fed through a welding torch, which is accompanied by a shielding gas. This gas protects the weld pool from contamination, resulting in clean and robust welds. MIG welding is known for its ease of use and is ideal for welding a variety of metals, including steel, aluminium, and stainless steel.

Best Features of MIG Welding

- High Speed: MIG welding is known for its fast deposition rates, making it suitable for applications that require quick and efficient welding.

- Versatility: It can be used on a wide range of materials and thickness.

- Minimal Cleanup: MIG welds are generally clean and require less post-weld cleaning.

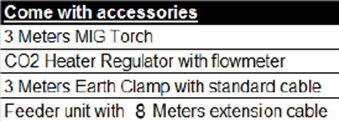

What Does a MIG Welding Machine Comes With?

A typical Danox MIG welding machine includes the welding torch, heater regulator, earth clamp, and wire feeder unit with extension cable.

Delve deeper into our MIG welding torch on Guide to Choosing the Right MIG Accessories to gain in-depth knowledge of how MIG torches can elevate your welding projects.

What is TIG Welding?

TIG welding, or Tungsten Inert Gas welding, is known for its precision and versatility. It uses a non-consumable tungsten electrode to create the arc and a separate filler rod for adding material to the weld. TIG welding is highly regarded for its clean and aesthetically pleasing welds, making it a preferred choice for applications where appearance matters.

Best Features of TIG Welding

- Precision: TIG welding allows for precise control over the heat input and weld pool, resulting in high-quality, detailed welds.

- Versatility: It can be used on various metals, including exotic alloys and thin materials.

- Clean Welds: TIG welding produces minimal spatter and minimal cleanup.

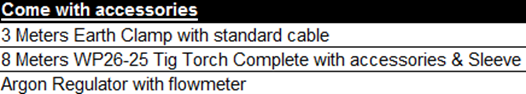

What Does a TIG Welding Machine Comes With?

A standard Danox TIG machine comprises a welding torch, earth clamp and argon regulator with flowmeter.

Explore our guide on How to Select the Right Accessories for Your TIG Torch for insights into torch selection, components, and finding the perfect torch for your welding needs.

What is ARC Welding?

ARC welding, or Shielded Metal Arc Welding (SMAW), is one of the oldest and most straightforward welding techniques. It uses a consumable electrode covered with a flux core to create an arc and produce welds. While it may not provide the same level of precision as TIG or MIG welding, it is exceptionally versatile and well-suited for heavy construction and fieldwork.

Best Features of ARC Welding

- Portability: ARC welding equipment is relatively compact and can be used in remote locations.

- Versatility: It can handle a wide range of materials and thickness.

- No Gas Required: Unlike MIG and TIG welding, ARC welding doesn’t require shielding gas, making it a cost-effective choice.

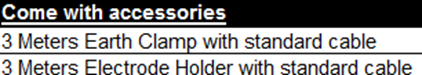

What Does an ARC Welding Machine Comes With?

A standard Danox ARC machine includes earth clamp and electrode holder, both with cable.

What is Plasma Cutting?

Plasma cutting is a cutting method that uses a high-velocity jet of ionised gas to melt and remove material. It is not welding per se, but it’s often associated with welding due to its common use in preparing metal pieces for welding or cutting metal during fabrication.

Best Features of Plasma Cutting

- Speed: Plasma cutting is known for its exceptional cutting speed, making it suitable for industrial applications.

- Versatility: It can cut through a variety of materials, including metals and non-conductive materials.

- Clean Cuts: Plasma cutting typically results in clean, precise cuts with minimal.

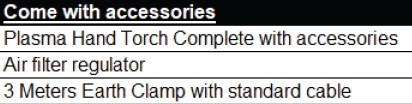

What Does a Plasma Cutting Machine Comes With?

A standard Danox Plasma cutting machine includes the torch, air filter regulator, and earth clamp with cable.

Conclusion

The choice between MIG, TIG, ARC, or Plasma welding depends on your specific welding needs and preferences. While MIG and TIG welding are commonly used for creating strong, aesthetically pleasing welds, ARC welding’s portability and cost-efficiency make it a favourite for certain applications. Plasma cutting, on the other hand, is all about precision cutting and speed.

To explore our range of welding and cutting machines, visit Danox Welding’s product page. Whether you’re a seasoned welder or just starting, our machines are designed to meet your welding and cutting requirements. For more welding insights, don’t forget to check our blog articles on MIG, TIG, and Plasma torch accessories for that extra edge in your welding projects.