To achieve exceptional welds, it is essential to understand and choose the right MIG torch accessories. These seemingly small components play a big role in ensuring that your welding process runs smoothly and produces clean, precise welds.

In this comprehensive guide, we’ll delve into the details of key MIG torch accessories. We’ll not only explain their functions but also provide insights into selecting the right size and type to enhance your welding performance. Our ultimate goal is to help you make informed decisions when purchasing spare parts and encourage you to explore our website for a wide range of MIG accessories and spare parts.

1. Gas Nozzle

Function

The gas nozzle directs the flow of shielding gas over the welding arc to protect the weld pool from atmospheric contamination. It plays a crucial role in ensuring a clean and strong weld.

Choosing the Right Nozzle

Select a nozzle size and shape that matches your welding application. A larger nozzle can provide better gas coverage for larger welds, while smaller nozzles are suitable for intricate work.

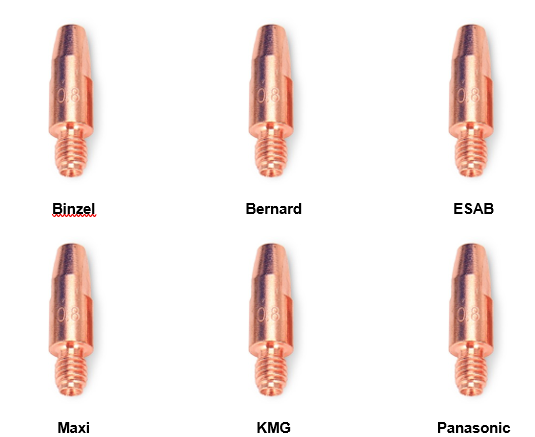

2. Contact Tip

Function

The contact tip is the point where the welding wire makes contact with the workpiece. It conducts the electrical current, creating the arc. A properly functioning contact tip ensures a stable arc and consistent wire feeding.

Choosing the Right Contact Tip

Consider the wire diameter you’re using. Contact tips come in various sizes, ranging from 0.8MM to 1.6mm here at Danox Welding. So choose one that matches your wire diameter for optimal performance.

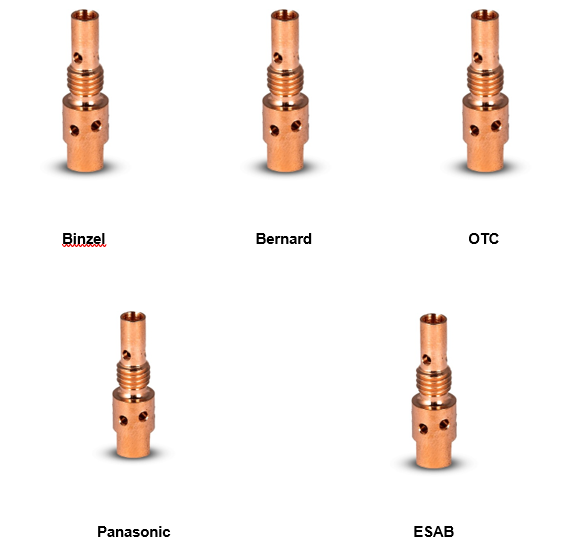

3. Tip Holder

Function

The tip holder, or tip adaptor, secures the contact tip within the MIG torch. It’s essential for maintaining the alignment and stability of the contact tip during welding.

Choosing the Right Tip Holder

Ensure the tip holder is compatible with your MIG torch model. It should securely hold the contact tip in place.

4. Swan Neck

Function

The swan neck is the curved part of the MIG torch that connects the torch body to the contact tip assembly. It provides flexibility and maneuverability during welding, especially in tight spaces.

Choosing the Right Swan Neck

Select a swan neck with the appropriate angle and length to suit your welding needs. Different angles and lengths offer different levels of accessibility.

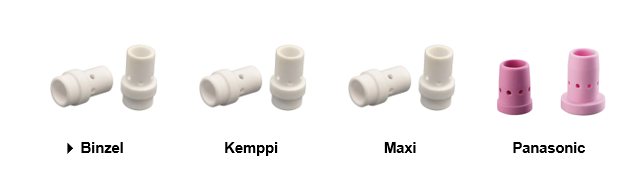

5. Gas Diffuser/Orifice

Function

The gas diffuser evenly distributes shielding gas around the welding wire as it exits the torch, This ensures uniform gas coverage over the weld pool, contributing to cleaner and more stable welds.

Choosing the Right Gas Diffuser

Gas diffusers are designed for specific MIG torch models. Ensure compatibility with your torch when selecting a gas diffuser. Gas diffusers are replaceable and should be inspected regularly for blockages or damage.

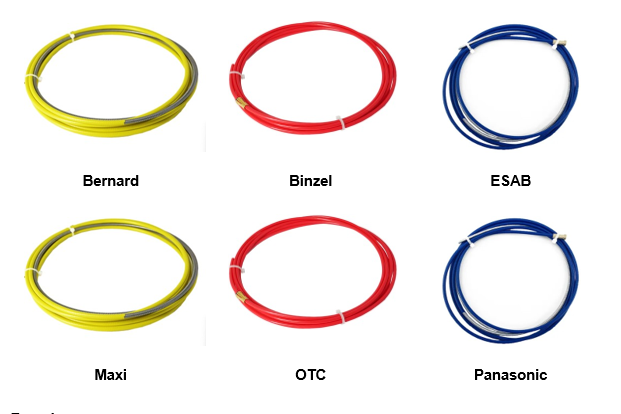

6. Spring Liner/Teflon Liner

Function

The spring liner is a critical component within the torch cable assembly. It guides the welding wire from the wire feeder to the contact tip smoothly. A properly maintained spring liner prevents wire kinking or bird nesting, which can disrupt the welding process. Liner selection should match the wire diameter and material for optimal wire feeding.

Choosing the Right Spring Liner/Teflon Liner

Match the spring liner to your wire diameter and material. Proper sizing ensures smooth wire feeding and reduces the risk of wire-related issues.

Conclusion

Choosing the right MIG torch accessories is a crucial step toward achieving precision and excellence in your welding projects. By understanding the functions of components and choosing the right size and type for your specific needs, you can significantly enhance your welding performance.

At Danox Welding, we offer a wide range of MIG torch accessories and spare parts to help you achieve the best results in your welding endeavors. Explore our products and take your welding precision to the next level