Have you ever wondered what the labels on your cutting or grinding discs mean? Are they just a jumble of letters and numbers, or is there important information that you’re overlooking? Perhaps a new welder has asked you about these markings, and you weren’t entirely sure how to respond.

Have you ever wondered what the labels on your cutting or grinding discs mean? Are they just a jumble of letters and numbers, or is there important information that you’re overlooking? Perhaps a new welder has asked you about these markings, and you weren’t entirely sure how to respond.

If so, you’re in the right place! This blog dives deep into the meaning behind the labels on cutting and grinding discs so that you can confidently select the right disc for your welding tasks.

You may also like: Common Metals Used in Welding – Types & Properties

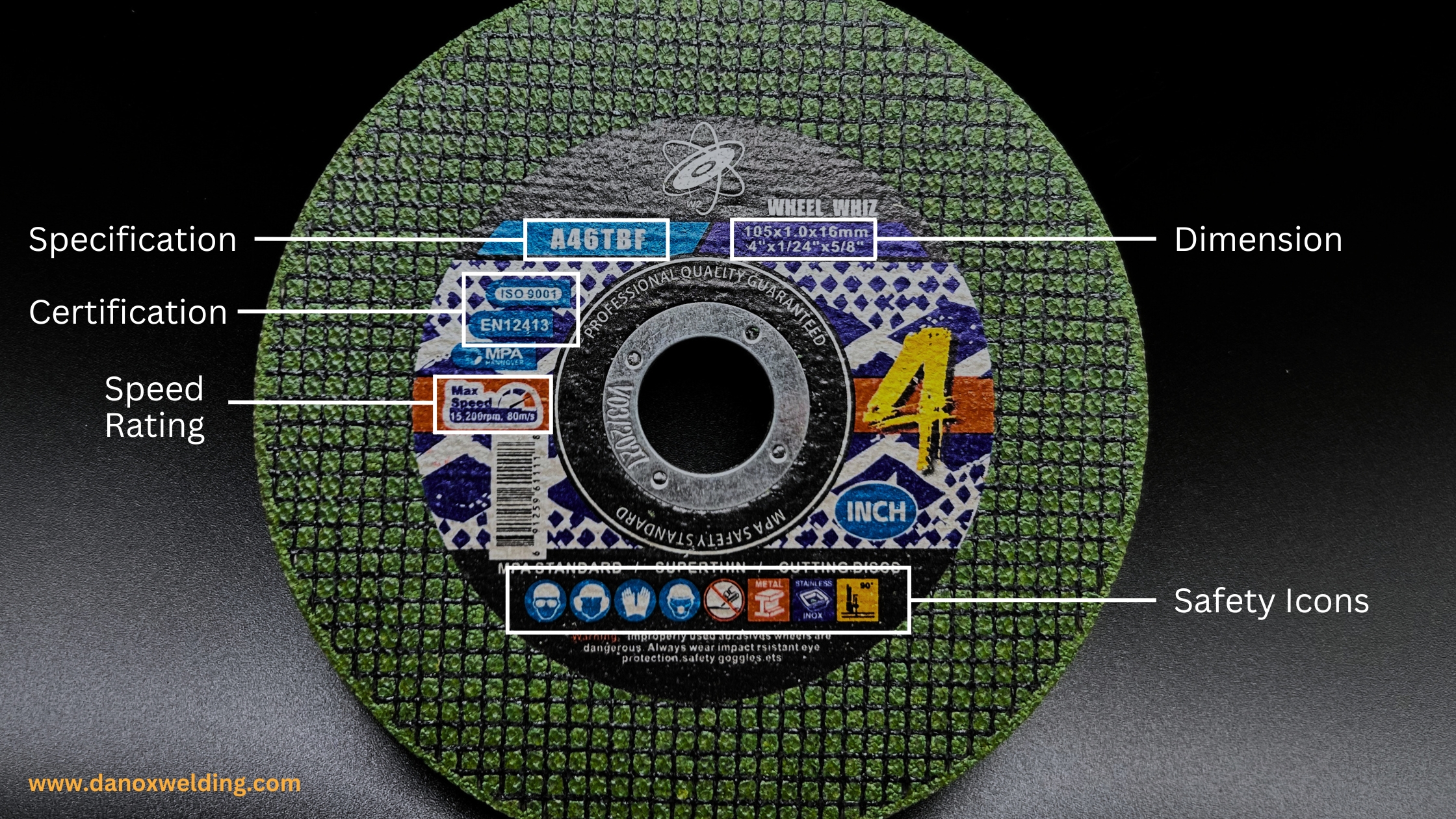

Types of Markings on Cutting & Grinding Discs

Every abrasive disc carries labels that provide key information about its specifications and limitations. Understanding these labels can significantly improve both your efficiency and safety while working. Below are the five primary types of markings commonly found on cutting and grinding discs:

- Specification

- Dimension

- Certification Markings

- Speed Rating

- Safety & Restriction Icon

1.Specification Breakdown

The specification marking refers to the abrasive properties and characteristics of the disc. Typically, this information is found as a combination of letters and numbers on the disc, such as A46T-BF or C24R-BF. Understanding these codes can help you choose the right disc for your specific needs.

Abrasive Material

The first letter of the specification code indicates the abrasive material used in the disc:

Letter | Material | Application |

A | Aluminium Oxide | Used primarily for cutting and grinding metals such as steel and iron. |

C | Silicone Carbide | Used for non-metallic materials such as stone, concrete, and ceramics. |

Z | Zirconia Alumina | Used for tough and durable cutting on metals and alloys. |

S | Sintered Abrasives | Used for extremely hard materials such as ceramics or superalloys. |

Grit Size

The number following the abrasive material letter indicates the size of the abrasive particles (grit):

Numeral | Size | Application |

16 – 36 | Coarse | Used for heavy material removal, cutting, and rough grinding. |

46 – 60 | Medium | Suitable for general-purpose cutting and grinding. |

80 – 120 | Fine | Used for finishing, polishing, or precision grinding. |

Hardness Grade

The alphabetical character after the grit size denotes the hardness of the bond holding the abrasive particles together:

Range | Hardness |

A to F | Very Soft |

G to K | Soft |

L to O | Medium Soft |

P to S | Medium Hard |

T to W | Hard |

X to Z | Very Hard |

Bond Type

The bond type refers to the material that holds the abrasive particles together:

Letter | Bond | Application |

B | Resinoid Bond | A synthetic resin bond, often used for high-speed cutting and grinding, offering shock resistance and flexibility. |

V | Vitrified Bond | A ceramic/glass-like bond, providing precision and heat resistance, generally used for grinding wheels. |

BF | Resinoid, Fiber-Reinforced Bond | A bond made from resinoid material with added fibre reinforcement, giving extra strength and durability, typically for heavy-duty operations. |

2. Dimensions

All discs will have the dimension listed on its label. The dimension is usually measured in millimetres (MM) or inches. You can find it being measured in Diameter by Thickness by Hole Size.

Measurement = Diameter x Thickness x Hole Size

3.Certification Markings

Various certifications indicate that the disc meets industry standards for safety, performance, and quality. Some common certifications include:

EN 12413 | A European safety standard for bonded abrasive products. It ensures high safety levels during cutting and grinding operations, reducing the risk of accidents.

This certification signifies that specific tests have been done to ensure discs can handle the high speeds and pressures encountered during operation. |

ISO 9001 | This is a quality management certification that ensures products are manufactured consistently with high-quality standards. While ISO 9001 isn’t specific to cutting discs or grinding discs, it indicates that the manufacturer follows stringent quality process. The certification focuses on process optimisations and quality control to ensure products meet regulatory requirements. |

oSa Certification | The Organisation for the Safety of Abrasives (oSa) is an international safety certification for abrasives. Discs with this certification have been rigorously tested and meet high safety standards, particularly in preventing disc breakage under stress. |

ANSI B7.1 | This is an American safety standard for the use, care, and protection of abrasive wheels. It focuses on the safe use of abrasive wheels, particularly in industrial settings. |

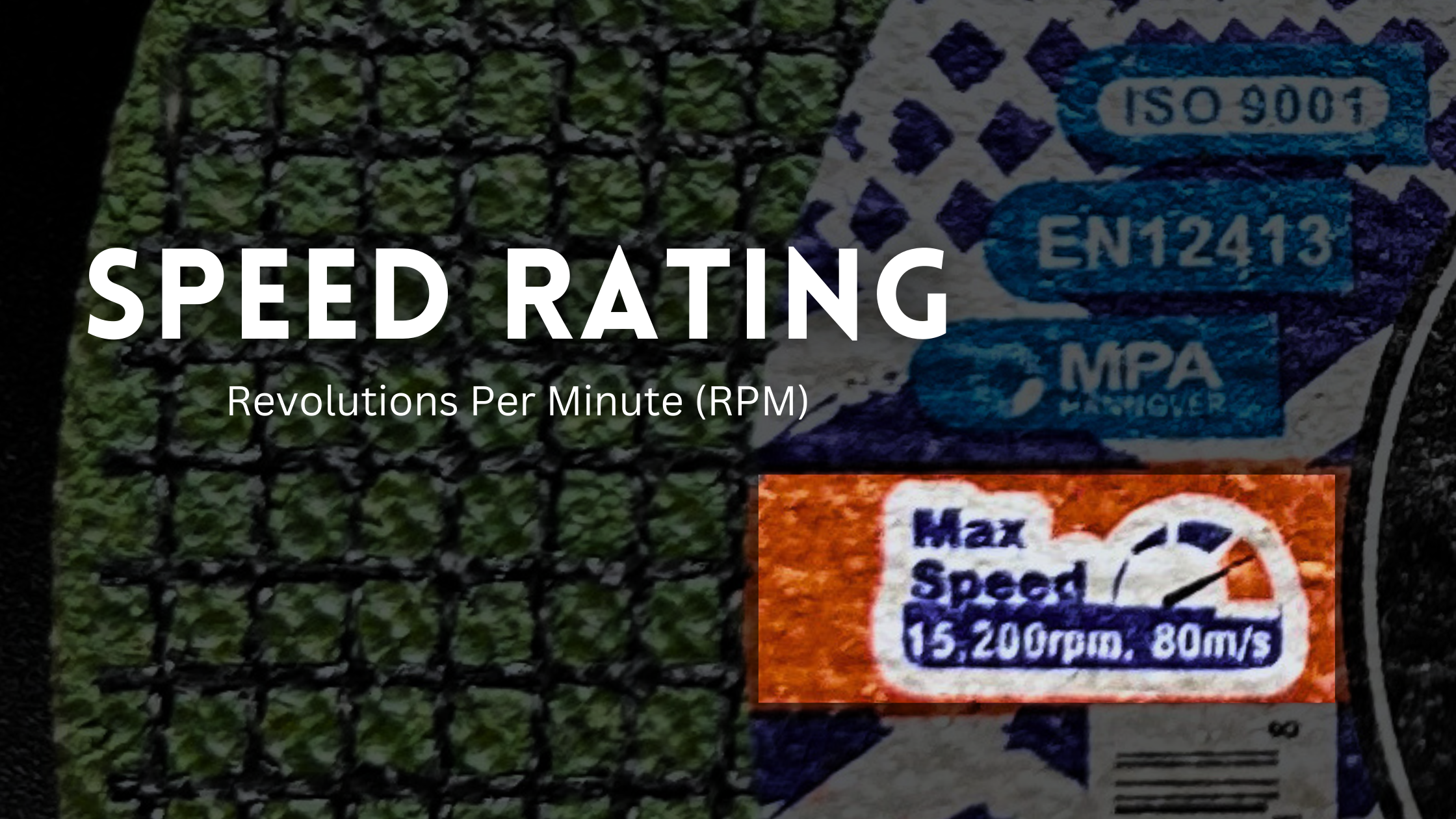

4. Speed Ratings

A cutting and grinding disc must always include its speed. It’s crucial to have the maximum speed the disc is rated for clearly indicated on the disc. Unit is measured in Revolutions Per Minute (RPM), or m/s.

The maximum RPM rating indicates the highest speed at which the disc can safely operate. Exceeding this speed can cause the disc to break apart, leading to dangerous accidents.

For example, a disc with a max RPM of 12,200 should only be used on a grinder that spins at or below this speed. If the grinder exceeds the disc’s maximum speed, the centrifugal forces could cause the disc to shatter.

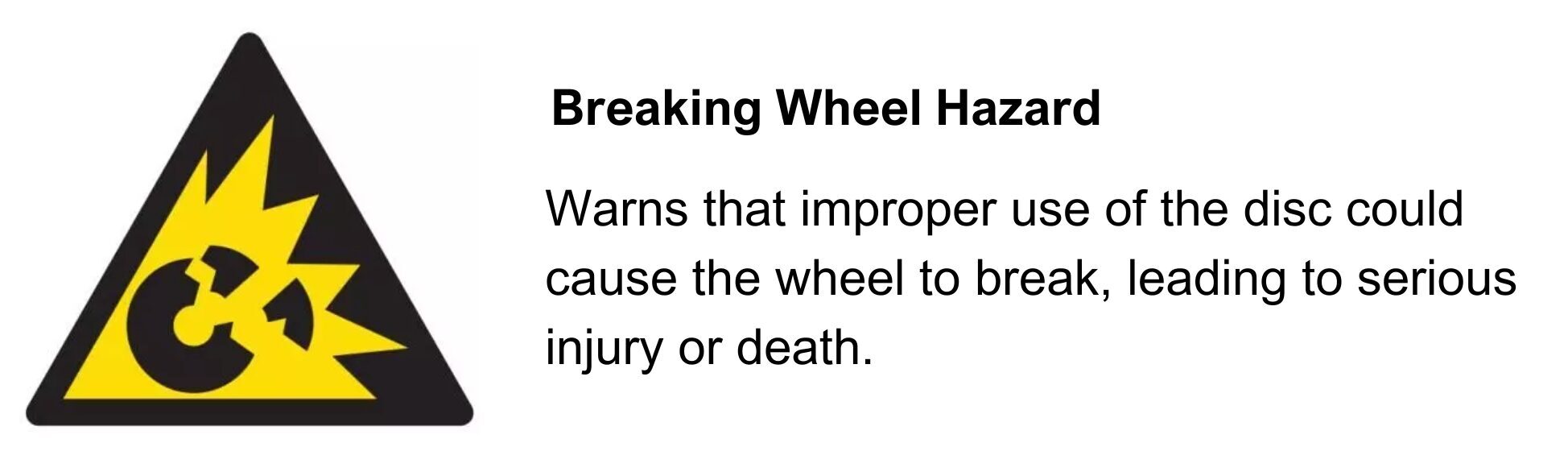

5. Safety Icon

Manufacturers print various safety icons on the discs to inform users about the required precautions, hazards, and proper use of the tools. Below is a breakdown of different safety icons commonly found on discs and what they mean.

Hazard Alert Icons

These icons warn the user of potential hazards associated with improper use.

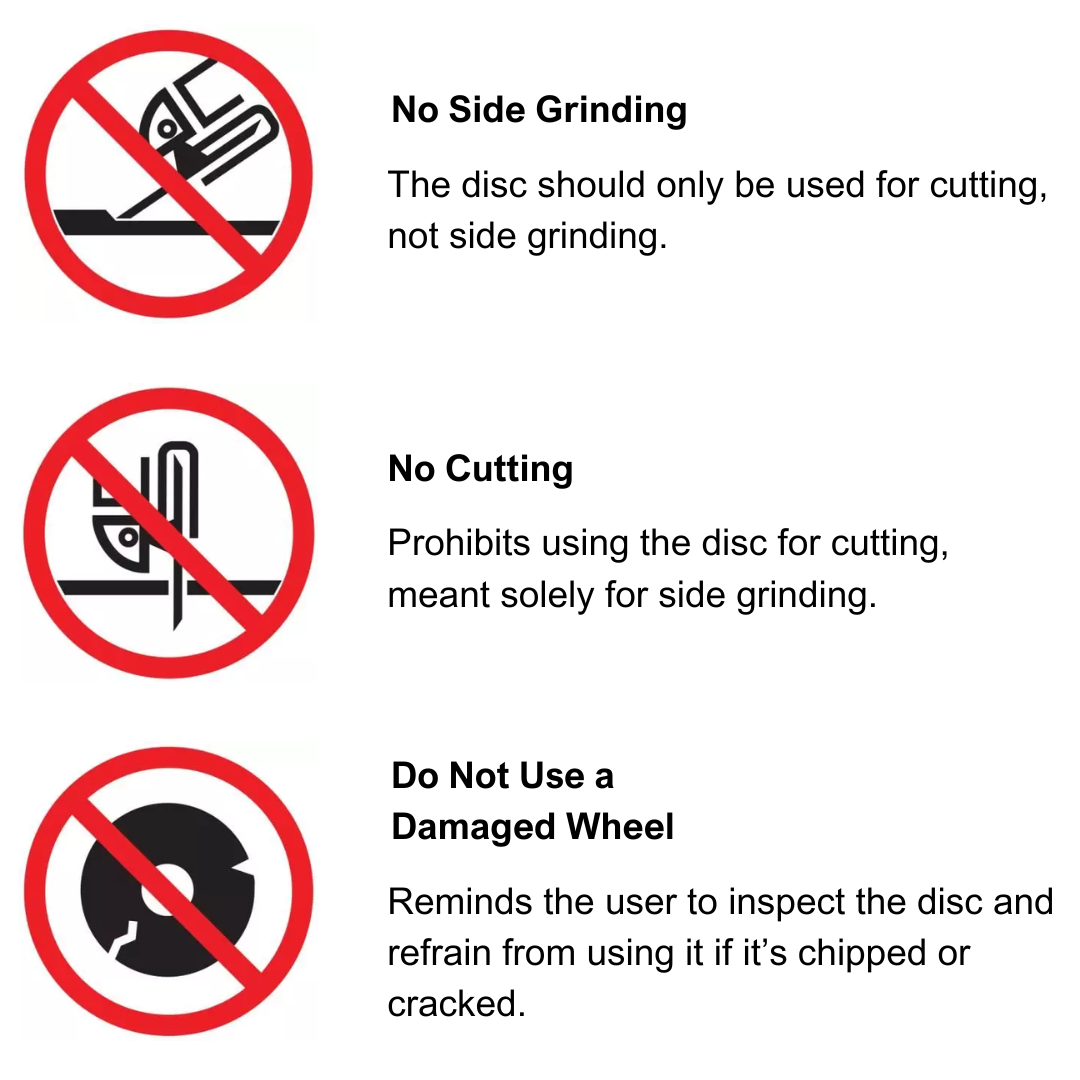

Prohibition Icons

These icons indicate actions that should be avoided to prevent accidents or damage to the tool.

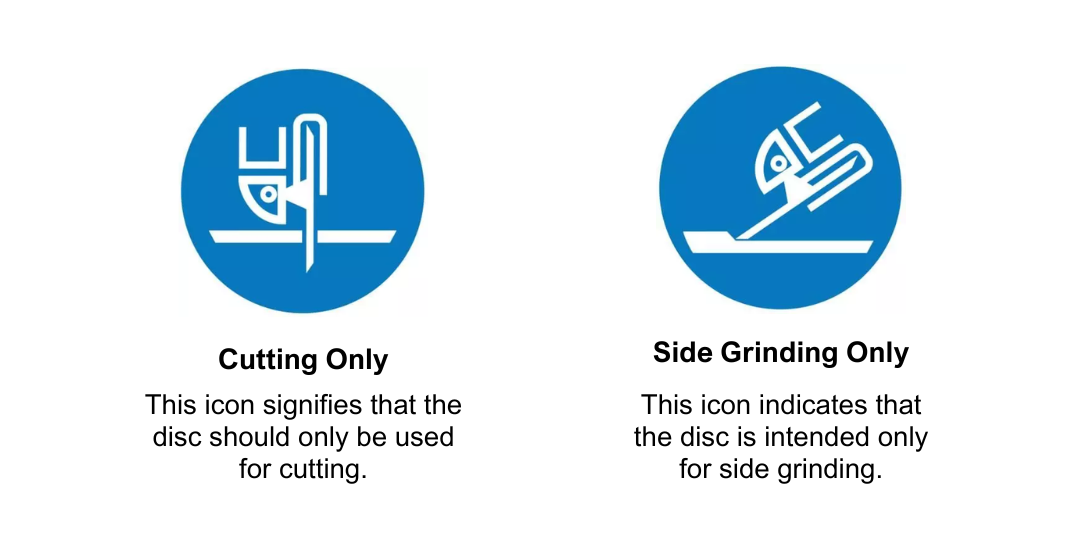

Mandatory Action Icons

These icons instruct the user on the necessary precautions and safety measures to follow.

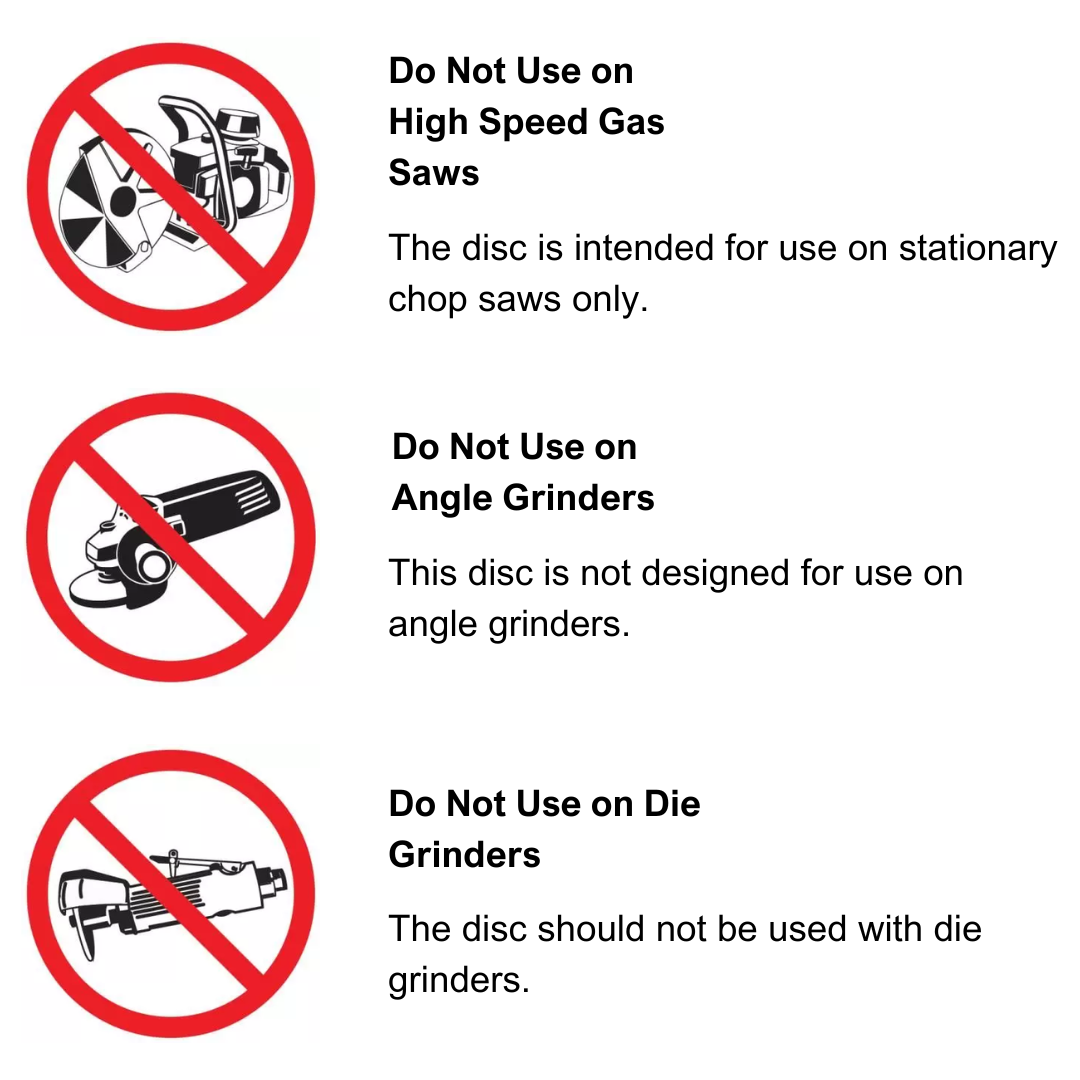

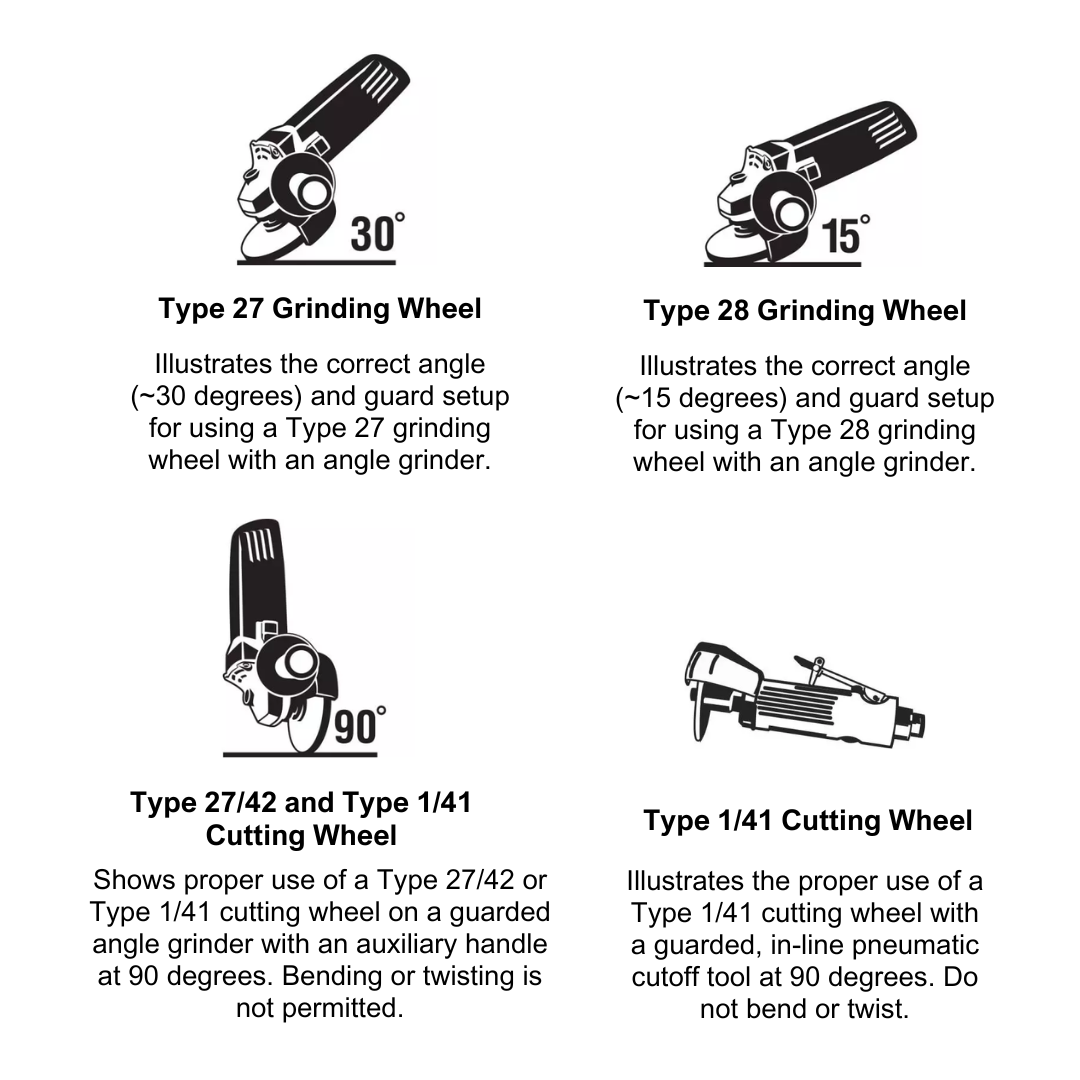

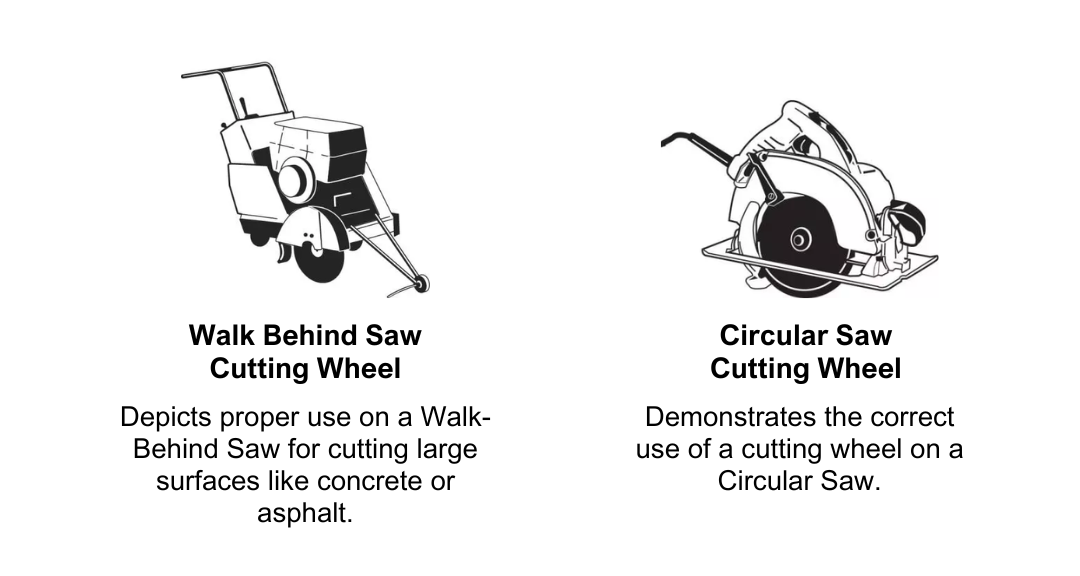

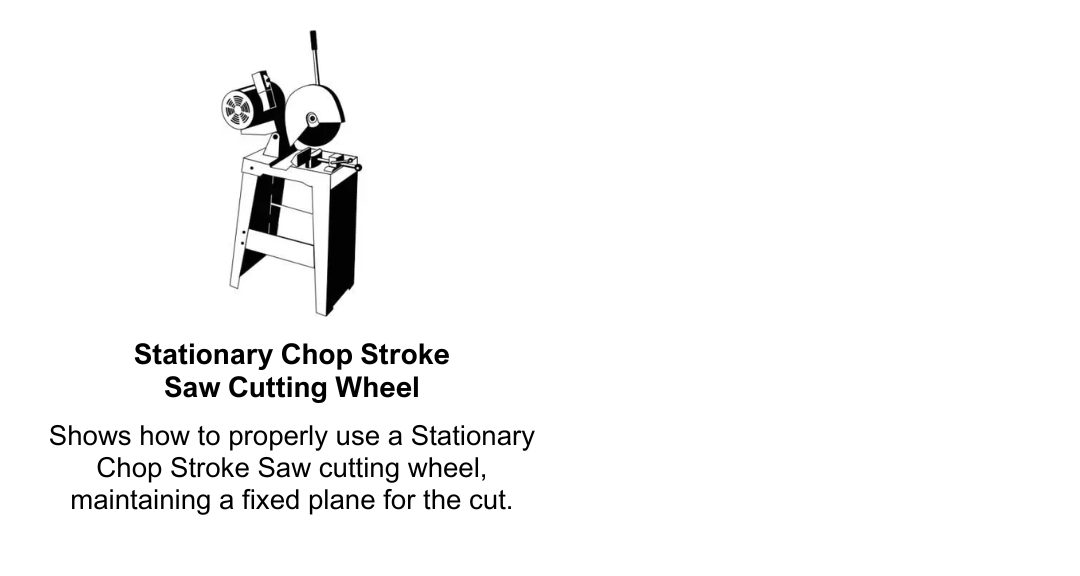

Proper Machine Use Icons

These icons depict the appropriate machine or tool setup for using the disc.

Power of Knowing

Understanding the labels on your cutting and grinding discs not only helps in selecting the right tools for the job but also ensures safe and efficient operation.

Next time you pick up a disc, take a moment to read the specifications, speed ratings, and safety icons. Doing so will improve your productivity and significantly reduce the risk of accidents. If in doubt, always consult the disc’s manual or contact a professional for guidance.