In the world of welding, precision and finesse often find their home in a welding technique known as TIG welding. If you’ve ever wondered what TIG welding is, how it works, and why it’s renowned for its precision, you’re in the right place. In this article, we’ll demystify the art of TIG welding, explore the components of a TIG torch, and weigh the pros and cons of choosing TIG welding for your projects

What is TIG Welding?

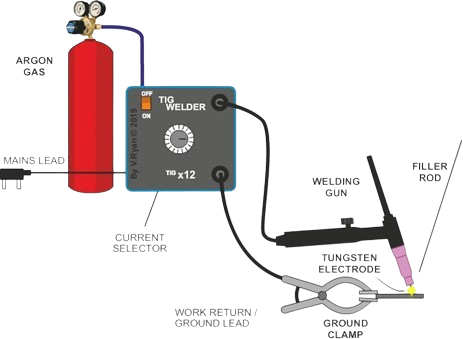

TIG stands for Tungsten Inert Gas welding, although it’s often referred to as GTAW (Gas Tungsten Arc Welding). It is a welding method renowned for its precision, cleanliness, and versatility. TIG welding involves the use of a non-consumable tungsten electrode, an inert gas (usually argon), and a filler material (if needed). The tungsten electrode creates the arc, and the inert gas shields the weld from contamination, resulting in a clean and highly-controlled weld.

The TIG Torch: Gateway to Precision

At the heart of TIG welding is the TIG Torch, a crucial tool that facilitates the welding process. Here’s a breakdown of its key components:

1. Tungsten Electrode:

The non-consumable tungsten electrode is the backbone of TIG welding. It is designed to withstand extremely high temperatures and forms the arc that melts the base metals and filler material.

2. Collet & Collet Body:

The collet and collet body work in unison to secure the tungsten electrode and control its positioning within the torch. They play a crucial role in maintaining arc stability.

3. Back Cap – Long, Medium, Short:

The back cap attaches to the rear of the torch and holds the collet body and collet in place. It can come in different lengths to accommodate various welding applications.

4. Alumina Cup:

The alumina cup, also known as the nozzle, is where the inert gas flows out to shield the weld zone. Its design and size influence the shielding gas coverage, affecting the quality of the weld.

5. Insulator:

The insulator separates the alumina cup from the torch body, preventing electrical contact and ensuring safe operation.

6. Cup Gasket:

The cup gasket provides a seal between the alumina cup and the insulator, helping to maintain the integrity of the shielding gas.

7. Torch Body:

The torch body houses all the components and directs the arc. It also provides a stable structure for the torch.

8. Gas Lens Collet Body:

The gas lens collet body is an optional but highly beneficial component that helps distribute the shielding gas more evenly, reducing turbulence and enhancing weld quality.

9. Gas Lens Alumina Cup:

Similar to the standard alumina cup, the gas lens alumina cup aids in distributing shielding gas for improved weld quality.

10. Torch Handle:

The torch handle provides a comfortable grip and includes controls for amperage adjustment, making it easier for the welder to work effectively.

Pros & Cons of Choosing TIG Welding

PROS | CONS |

PRECISION TIG welding offers exceptional control and precision, making it ideal for intricate, detailed work. | COMPLEX TECHNIQUE TIG welding requires a higher level of skill and practice compared to some other welding methods. |

CLEAN WELDS The inert gas shield creates clean, slag-free welds with minimal spatter. | SLOWER SPEED Due to its precision, TIG welding can be slower than other methods, which may not be suitable for high-production projects. |

| VERSATILITY | LIMITED THICKNESS |

| TIG welding can be used on a wide range of metals, including stainless steel, aluminium, and even exotic alloys. | It may not be the best choice for extremely thick materials where faster welding processes are more efficient. |

LOW HEAT The low heat input minimises distortion and the need for extensive post-weld cleanup. |

Mastering the Art of TIG Welding:

TIG welding is often likened to a fine art. Its precision and attention to detail make it a favourite among artisans, aerospace manufacturers, and anyone who values the highest quality welds. However, it requires dedication and practice to become proficient.

Whether you’re just starting your journey into welding or you’re a seasoned professional, understanding TIG welding opens up a world of possibilities for creating precise, clean, and beautiful welds.

At Danox Welding, we offer a range of TIG welding equipment, including TIG machines, spare parts, tungsten electrodes, and shielding gases to help you master this art form. Explore our products and embark on a journey of precision in every bead

DANOX TIG200 INVERTER DC TIG WELDING MACHINE

✓ Stable arc without spatter

✓ Good shaping & less deformation

✓ Real time display of welding current