Imagine a welding technique so precise that it can craft intricate designs with the delicacy of a surgeon’s hand, yet so powerful that it can cut through metal like a hot knife through butter. This is the captivating world of plasma welding.

In this article, we’ll venture into the fascinating realm of plasma welding, delving into the components and accessories necessary for this method, and weighing the pros and cons of choosing plasma welding for your welding projects. Get ready to unleash the precision and power of plasma welding.

Understanding Plasma: The Heart of Plasma Welding

At the core of plasma welding lies the phenomenon of plasma itself. Plasma is the fourth state of matter, is neither a solid, liquid, nor gas. It’s created by ionising a gas, resulting in a unique state characterised by a mixture of ions and free electrons. This highly charged state generates an astonishingly hot and focused heat source.

It’s this extraordinary property that makes plasma welding a force to be reckoned with in the world of welding.

What is a Plasma Torch?

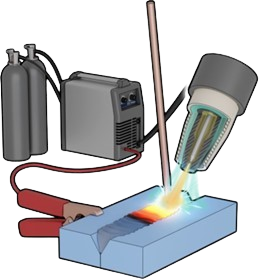

The instrument that serves as the artisan’s brush in the world of plasma welding is the plasma torch. This torch is meticulously designed to create and control the plasma arc, providing welders with the precision and control they need. It’s the vital tool that makes plasma welding possible.

A plasma torch is an intricate piece of equipment with several key components and accessories:

- Nozzle:

The nozzle shapes and focuses the plasma arc, creating a fine, high-velocity stream of plasma gas for precise welding and cutting. - Electrode:

Typically made of tungsten, the electrode serves as the cathode in the plasma arc. It helps maintain arc stability and conductivity. - Gas Supply:

Plasma welding requires a supply of plasma gas, which can be argon, hydrogen, or a mixture. In some cases, a shielding gas may also be used. - Cooling System:

Plasma torches generate significant heat, necessitating a cooling system to prevent overheating. - Control Panel:

Modern plasma torches often feature advanced control panels, allowing welders to fine-tune parameters such as current, gas flow, and arc voltage for precise welding and cutting. - Earth Clamp:

The earth clamp, or ground clamp, is an accessory that connects the workpiece to the welding machine’s It ensures a stable electrical circuit and safe welding operations. - Pressure Regulator with Filter:

This accessory is crucial for regulating the pressure of the plasma gas, ensuring a consistent and controlled flow. The filter component helps remove impurities from the gas stream, enhancing weld quality.

Pros & Cons of Choosing Plasma Welding

PROS | CONS |

PRECISION Plasma welding offers unparalleled precision and control, making it ideal for tasks requiring intricate detail work. | COMPLEXITY Plasma welding can be more complex and may require a higher level of skill compared to some other welding methods. |

CLEAN WELDS The focused plasma arc results in clean, high-quality welds with minimal spatter. | COST High-quality plasma welding equipment can be more expensive than some other welding setups. |

VERSATILITY Plasma welding is compatible with a wide range of conductive materials, including stainless steel, aluminium, copper, and more. | LIMITED THICKNESS It may not be suitable for extremely thick materials or heavy-duty welding applications. |

HIGH ENERGY DENSITY Plasma welding generates an intensely concentrated heat source, enabling deep penetration with low heat input. |

Exploring the World of Plasma Welding

Plasma welding is a realm where precision marries power. Whether you’re a seasoned welding professional or just beginning your journey, comprehending plasma welding opens doors to achieving the highest quality welds and precision cuts.

At Danox Welding, we offer a range of plasma welding equipment, including plasma welding machines, torches, electrodes, and other accessories, to help you master this precise welding method. Explore our products and unlock the potential of plasma welding for your welding projects.

EX-TRAFIRE 100SD PLASMA CUTTING MACHINE

✓ Easily accessible filter regulator

✓ Plate thicknesses up to 10mm+

✓ Fixed torch with flexible torch package